Evaluación de la Integridad de Pozos Productores o Inyectores

Intensidad: 40 horas

Horario: 8:00 am a 5:00 pm

Código: C19130

Incluye: Almuerzos, refrigerios, memorias y certificado de asistencia otorgado por ELITE TRAINING.

Certificación: Elite Training, otorgará diploma de asistencia a los participantes que asistan como mínimo al 80% de la intensidad horaria.

CONDICIONES DE PARTICIPACIÓN:

Descuentos:

Por pronto pago:

- 10% por pago hasta fecha por confirmar..

- Aplica para personas naturales y empresas que pagan de contado.

- Requiere el envío del comprobante de pago de la inscripción al curso.

- No acumulable con el descuento por confirmación de participación.

Por confirmación de participación:

- 10% por confirmar tu participación hasta fecha por confirmar..

- Aplica para empresas con convenio de pago posterior al curso.

- Requiere el envío de la orden de facturación o el documento equivalente.

- No acumulable con el descuento por pronto pago.

Para grupos:

5% para el 2do. participante de la misma empresa

10% para el 3er participante en adelante de la misma empresa

Fecha límite de cancelación de participación: fecha por confirmar. En caso de cancelar la participación después de esta fecha, el cliente deberá pagar la totalidad del valor del curso y este valor se abonará para cualquier otro curso de su interés o se permitirá el cambio del participante inscrito hasta 2 días hábiles antes del inicio del curso.

- Nos reservamos el derecho de hacer ajustes en la agenda académica y fechas límite de confirmación.

- El curso será formalmente confirmado solo después de la fecha límite de cancelación de participación, o antes si previamente se ha alcanzado el número de inscritos necesario, que garantice el éxito del curso.

- Si se cancela la realización del curso, efectuaremos el reembolso de pagos, a aquellos participantes que los hayan efectuado previamente.

INSTRUCTOR: Ing. Carlos Alvarez

Ingeniero de Petróleo. Realizó Programa de Postgrado en Gerencia de Ingeniería en el IESA, Venezuela y un Programa Ejecutivo para Gerentes Petroleros en The Institute for Petroleum Development, Austin, Texas.

Posee 39 años de experiencia en la industria de petróleo y gas, abarcando las áreas de ingeniería, tecnología de producción, operaciones de producción, planificación estratégica y control de la gestión de negocios. Es considerado experto en la evaluación e implementación de tecnologías de alta eficiencia y rentabilidad.

Inició su carrera profesional en 1979 en actividades de ingeniería de yacimientos, perforación, completamiento y rehabilitación de pozos y en ingeniería y operaciones de producción.

Desde 1991 desempeñó posiciones de gerencia y ejecutivas en Planificación, Evaluación Técnica-Económica de Proyectos, Coordinación de Operaciones y Tecnologías de Producción.

Desde 2003 es consultor e instructor internacional para la industria petrolera, de la cual es miembro de la junta directiva y consultor internacional. Ha trabajado en un gran número de asignaciones en diversas compañías nacionales y privadas en Norte y Sur América.

Ha dictado numerosos cursos técnicos en Medio Oriente, Asia, África, Norte y Sur América. Domina con maestría software comercial aplicado a ingeniería de petróleo, software para análisis de riesgo y software para evaluaciones económicas.

Contenidos

Beneficios y Alcance:

- Evaluar el importante papel que desempeña un adecuado diseño de pozos

- Revisar las condiciones en las que operará el pozo durante su ciclo de vida útil y cómo se afectan la seguridad, los riesgos y la economía de las operaciones.

- Analizar las «barreras», tales como los revestimientos, la cementación y varios equipos utilizados en la terminación de pozos.

- Conocer los efectos de corrosión y erosión en las barreras, problemas con las cargas, presión y temperatura que afectan la integridad de las barreras.

- Comprender los estándares sobre Integridad de Pozos de ISO, Norsok, API y la legislación aplicada en algunos países líderes en este tema.

- Entender la importancia y aprender a documentar y compartir información desde el diseño y la construcción de pozos, y posteriormente, durante el monitoreo, la inspección y la ejecución de pruebas especiales que permitan identificar situaciones inseguras en pozos.

- Cuantificar los riesgos en la ejecución de mantenimientos predictivos, preventivos y correctivos.

Dirigido a: Ingenieros de producción, perforación, rehabilitación y completamiento de pozos.

Metodología: Este curso comprende las normas y estándares sobre integridad que actualmente se aplican a pozos, tanto productores de hidrocarburos como inyectores, en las etapas de diseño, construcción y operación, bajo el criterio de ciclo de vida útil del pozo y haciendo énfasis en selección adecuada de equipos, monitoreo y supervisión de las operaciones de construcción, operación, intervención y mantenimiento.

El curso contiene una excelente base teórica, pero además se resuelven ejercicios y problemas, por lo que se recomienda que los participantes lleven ordenadores (laptops o tablets) con excel o su equivalente, para la generación de tablas y solución de ecuaciones.

Contenido: El material del curso está editado en Inglés, pero será dictado en Español.

INTRODUCTION TO WELL INTEGRITY

- History of Well Integrity

- The importance of well integrity

- Petroleum geology and reservoir review

- Introduction to the Norsok D-010 standard; structure and principles

- ISO and API Well Integrity Stardards

CASING DESIGN & APPLICABLE STANDARDS

- Drilling and casing program, characteristics of casing

- Shoe positioning: hypotheses to be considered, casing point, kick tolerance & well integrity

- Casing String Calculation: principles and assumptions, stress cases study (collapse, burst, tension, triaxial study, safety factors)

- Casing selection

CEMENTING: PRIMARY & REMEDIAL

- Techniques and job procedures: primary cementing, cement job design, job planning and preparation, casing running, cementing job, cementing calculations

- Cement equipment: pumps, mixers, cementing head, cement plugs

- Cement job evaluation: principles and interpretation of the cement logs: Sonic (CBL – VDL), Ultrasonic (USIT)

WELL COMPLETION EQUIPMENT DESIGN

- Well completion equipment: functions to be carried out and corresponding equipment

- Production string(s) configurations (vertical, deviated or horizontal, single or multi-zones)

- Production wellhead, tubing & connections, packers and accessories, bottom hole devices

- Subsurface safety valve (subsurface controlled, surface controlled)

- Calculation of tubing movement and forces

- Well completion preparation and Implementation

WELL INTEGRITY MANAGEMENT

- Well integrity management

- Well integrity design and standards; well construction/completion: casing, tubing, cement, produced fluids

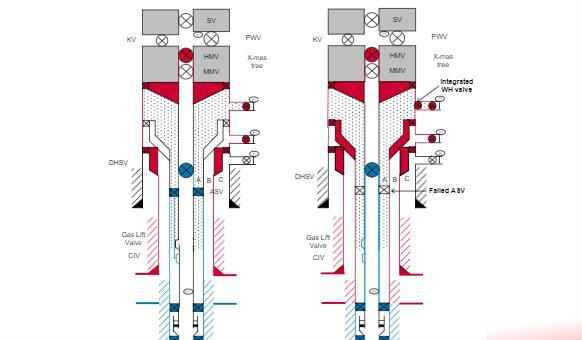

- Well barriers: definition, requirement & design. Wellhead and tree equipment: valves, seals, accessories, Safety valves: downhole, surface

- Minimum integrity requirements vs. well life cycle/phases, annulus pressure management, well integrity review

WELL HEAD INTEGRITY & MAINTENANCE

- Wellhead installation procedures

- Wellhead monitoring maintenance, function tests, pressure test, maintenance plan & execution

- X-mas tree specifications: natural flowing wells, artificial lift wells, gas wells

- X-mas tree equipment and selection (MV, SSV, SV, WV, choke)

FLOW ASSURANCE

- Well Engineer: Role and responsibilities over the operational life cycle of the well.

- Maximum Allowable Annulus Surface Pressure. The MAASP envelope

- Well Simulation: naturally flowing wells, artificial lift, skin effect

- Well stimulation and hydraulic fracturing

- Well services and well workover

- Corrosion monitoring and maintenance.

WELL SURVEILLANCE & RISK MANAGEMENT

- Surveillance of integrity in tubing and annulus

- Measuring and reporting well integrity

- Diagnostic testing and repair techniques for leaks

Risk Management

Reserva tu cupo

Si deseas registrarte para separar tu cupo y realizar el pago posteriormente, llena el siguiente formulario: